So, you’re knee-deep in the world of pharmaceutical manufacturing or perhaps you’re just starting to dip your toes in. Either way, cleaning validation is a critical aspect, and the documentation surrounding it can feel like navigating a maze. Let’s face it, ensuring that your equipment is squeaky clean and free from contaminants is not just about aesthetics; it’s about patient safety and regulatory compliance. And that’s where the whole idea of documentation for cleaning validation a protocol template comes into play. Think of it as your roadmap to success, a guiding document that outlines exactly how you’ll demonstrate and prove that your cleaning processes are effective and consistent.

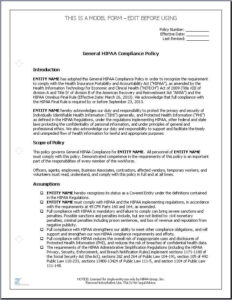

Without proper documentation for cleaning validation a protocol template, you’re essentially flying blind. Regulatory bodies like the FDA expect meticulous records, proving that you’ve considered all potential contaminants, established appropriate cleaning procedures, and verified their effectiveness. A well-structured protocol template provides a framework for capturing all this essential information, ensuring that nothing gets missed and that your validation efforts are defensible during audits. It’s not just about checking boxes; it’s about building a robust system that safeguards the quality and integrity of your products.

This article aims to demystify the process of creating and utilizing a cleaning validation protocol template. We’ll break down the key components, discuss best practices, and offer insights into how you can tailor your template to meet the specific needs of your manufacturing environment. By the end, you’ll have a much clearer understanding of how to approach cleaning validation documentation and how to leverage a template to streamline your efforts and ensure compliance.

Understanding the Importance of a Cleaning Validation Protocol Template

At its core, a cleaning validation protocol template serves as a blueprint for executing and documenting your cleaning validation studies. It’s not just a checklist; it’s a comprehensive document that outlines the scope, methodology, acceptance criteria, and responsibilities associated with the validation process. Think of it as a living document that evolves as your understanding of the cleaning process improves and your equipment or products change. Without a well-defined protocol template, you risk inconsistent validation practices, incomplete data collection, and ultimately, a failure to demonstrate the effectiveness of your cleaning procedures.

The benefits of using a cleaning validation protocol template are numerous. First and foremost, it promotes standardization and consistency. By following a pre-defined template, you ensure that all validation studies are conducted in a similar manner, making it easier to compare results and identify trends. This is particularly important in facilities with multiple production lines or where different operators are involved in the cleaning process. Standardisation minimizes variability and improves the reliability of your validation data.

Another key benefit is that a protocol template helps to ensure regulatory compliance. Regulatory agencies like the FDA have specific expectations for cleaning validation documentation. A comprehensive template addresses these requirements, ensuring that all necessary information is captured and presented in a clear and organized manner. This reduces the risk of audit findings and helps to demonstrate your commitment to quality and patient safety.

Furthermore, a well-designed protocol template can save you time and resources. By providing a structured framework for your validation studies, it eliminates the need to reinvent the wheel each time you need to validate a cleaning process. This streamlines the validation process and allows you to focus on analyzing the data and implementing improvements. It also provides a common language for your team, facilitating communication and collaboration.

Ultimately, the goal of cleaning validation is to ensure that your cleaning processes are effective at removing residues of previous products and cleaning agents from your manufacturing equipment. A robust protocol template is essential for achieving this goal, providing a framework for documenting your validation efforts and demonstrating your compliance with regulatory requirements.

Key Elements of a Comprehensive Cleaning Validation Protocol Template

So, what exactly goes into a comprehensive cleaning validation protocol template? Here’s a breakdown of some of the key elements you should consider including:

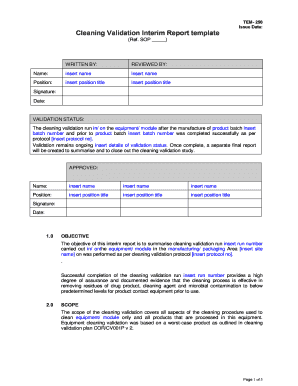

- Protocol Title and Identification: A clear and concise title that identifies the specific cleaning process being validated, along with a unique protocol number and revision history.

- Objective: A statement of the purpose of the validation study, clearly defining what you are trying to achieve.

- Scope: A description of the equipment, products, and cleaning agents covered by the validation study.

- Equipment Description: Detailed information about the equipment being cleaned, including its materials of construction and critical areas to be cleaned.

- Product Information: Information about the products manufactured on the equipment, including their toxicity and solubility.

- Cleaning Procedure: A detailed step-by-step description of the cleaning process, including the cleaning agents used, their concentrations, and contact times.

- Sampling Plan: A description of the sampling methods used to collect residue samples, including the location of the sampling points and the number of samples taken.

- Analytical Methods: A description of the analytical methods used to quantify the residues, including their sensitivity and specificity.

- Acceptance Criteria: Clearly defined acceptance criteria for the residue limits, based on factors such as toxicity, therapeutic dose, and visual cleanliness.

- Responsibilities: A clear assignment of responsibilities for each task in the validation process.

- Deviation Handling: A procedure for documenting and investigating any deviations from the protocol.

- Data Analysis: A description of how the data will be analyzed to determine if the cleaning process is validated.

- Conclusion: A summary of the results and a statement of whether the cleaning process has been validated.

- Approval Signatures: Signatures from the relevant personnel, such as quality assurance, manufacturing, and engineering.

These are just some of the key elements to consider when developing your cleaning validation protocol template. The specific content of your template will vary depending on the complexity of your cleaning processes and the requirements of your regulatory agency. However, by including these elements, you can create a comprehensive and effective template that will help you to demonstrate the effectiveness of your cleaning procedures and ensure the quality of your products.

Remember, your protocol template should be a living document that is reviewed and updated regularly to reflect changes in your cleaning processes, equipment, or regulatory requirements. By continually improving your template, you can ensure that your cleaning validation efforts are always up-to-date and compliant. It is important to periodically evaluate the template and make needed changes to reflect advancements in technology, changes in manufacturing processes, or updates to regulatory guidelines. Regular reviews ensure that the documentation for cleaning validation a protocol template remains relevant and effective in maintaining the highest standards of cleanliness and safety.

Properly documenting and following these protocols may seem tedious, but in the end, they are well worth the effort. The peace of mind that comes from knowing your processes are valid and safe is invaluable.

Compliance with regulations is not just a requirement; it’s a commitment to the wellbeing of your patients and the integrity of your products.