Ever wondered how facility managers and building owners keep track of all the complex mechanical and electrical systems within their properties? It’s a massive undertaking, from HVAC units to intricate wiring, lighting, and plumbing. Ensuring these systems are in good working order isn’t just about comfort; it’s crucial for safety, energy efficiency, and operational continuity. That’s where an M&E condition survey comes into play, providing a detailed snapshot of the current state of these vital assets.

But undertaking such a survey can be daunting without a clear, structured approach. Imagine trying to document every pipe, wire, and piece of equipment without a guiding framework – it would be chaotic, inconsistent, and likely miss critical details. This is precisely why having a robust m&e condition survey template is not just a nice-to-have, but an essential tool for any comprehensive assessment. A well-designed template ensures that every aspect is considered, recorded accurately, and presented in a way that facilitates informed decision-making.

What Goes Into an Effective M&E Condition Survey Template?

Creating a template for M&E condition surveys is about much more than just listing equipment. It’s about designing a structured document that guides the surveyor through a thorough inspection, ensuring consistency across different projects and even different assessors. A truly effective M&E condition survey template needs to be comprehensive, covering every angle from general information to specific observations and recommendations. Think of it as a roadmap for meticulous data collection, making sure no stone is left unturned when evaluating the health of a building’s critical systems.

The core of any good template lies in its ability to segment information logically. This means having dedicated sections for various types of data, allowing for easy input and subsequent analysis. From the moment a surveyor steps on site until the final report is compiled, the template should seamlessly facilitate the capture of all relevant details, preventing oversight and ensuring a complete picture of the M&E assets is formed. It should prompt the surveyor to look beyond obvious defects and assess the overall performance, remaining lifespan, and compliance of each system.

Key Sections to Include

- General Project Information: Site address, survey date, surveyor’s name, client details, and purpose of the survey.

- System Categories: Breakdowns for different M&E systems, e.g., HVAC (heating, ventilation, air conditioning), Electrical (distribution boards, lighting, power outlets), Plumbing (water supply, drainage), Fire Safety (alarms, sprinklers), Lifts, etc.

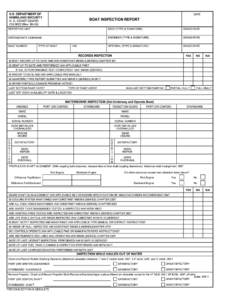

- Asset Register Details: For each piece of equipment, include its unique ID, manufacturer, model, serial number, installation date (if known), and last service date.

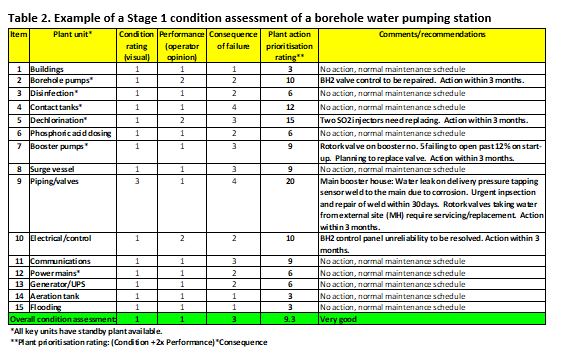

- Condition Rating: A standardized system (e.g., A=New, B=Good, C=Fair, D=Poor, E=End of Life) to objectively assess the current state. This often includes photographic evidence.

- Observations and Defects: Detailed descriptions of any issues found, including location, nature of the defect, and potential causes.

- Recommendations and Remedial Actions: Proposed solutions for defects, including estimated costs, priority level (e.g., urgent, medium, long-term), and suggested timelines for repair or replacement.

- Compliance and Statutory Requirements: Notes on whether systems meet current regulations and safety standards.

- Summary and Executive Overview: A high-level summary of findings and key recommendations for quick review by stakeholders.

By including these well-defined sections, an M&E condition survey template becomes more than just a checklist; it transforms into a powerful data collection and reporting tool. It ensures that critical information is consistently captured, regardless of who conducts the survey, leading to more reliable and comparable results. This structured approach is fundamental for effective long-term asset management and strategic planning.

Furthermore, a comprehensive template supports the generation of actionable insights. When data is collected uniformly, it’s easier to identify patterns, pinpoint recurring issues, and forecast future maintenance needs or capital expenditures. This foresight is invaluable for budgeting and operational efficiency, preventing unexpected breakdowns and costly emergency repairs by allowing for proactive intervention.

The Benefits of Using a Standardized M&E Condition Survey Template

Adopting a standardized M&E condition survey template offers a multitude of advantages that extend far beyond simply recording observations. It transforms the entire process of asset management, making it more efficient, reliable, and ultimately, more cost-effective. For any organization responsible for managing complex buildings, leveraging such a template is a strategic move that pays dividends in the long run.

One of the most significant benefits is the unparalleled consistency it brings to the survey process. When every surveyor uses the same framework, the data collected is uniform and comparable, no matter who is conducting the inspection or when it’s performed. This consistency is crucial for benchmarking the condition of various assets over time, identifying trends, and making informed decisions about maintenance, repair, or replacement. Without it, you’re left with disparate reports that are hard to synthesize into a coherent picture.

Moreover, a well-structured template drastically improves efficiency. Surveyors can work through inspections more quickly and methodically, knowing exactly what information needs to be captured. This reduces the time spent on site and minimizes the risk of forgetting crucial details, which would otherwise necessitate costly follow-up visits. The streamlined data entry also speeds up the reporting phase, allowing stakeholders to access critical information much faster and act upon it without delay.

Ultimately, the use of a standardized template leads to better decision-making and more accurate financial planning. With clear, consistent data on the condition of all M&E systems, building owners and facility managers can develop precise maintenance schedules, forecast capital expenditure requirements more accurately, and justify investments in upgrades or replacements. It provides the solid evidence needed to prioritize critical repairs, allocate budgets effectively, and ensure the longevity and optimal performance of building assets.

In the realm of facility management, the meticulous assessment of mechanical and electrical systems is paramount for operational excellence, safety, and energy efficiency. Implementing a carefully designed template for these condition surveys is not merely a procedural step but a foundational strategy. It empowers teams to conduct thorough, consistent, and insightful evaluations, transforming raw data into actionable intelligence.

By embracing such a systematic approach, organizations can move beyond reactive maintenance to a proactive asset management strategy. This shift leads to improved system reliability, reduced downtime, and significant long-term cost savings, ensuring that buildings remain safe, efficient, and fit for purpose for years to come. It’s a testament to how structured documentation can profoundly impact the strategic management of valuable building infrastructure.